We provide free proposals and quotes 24/7.

Feel free to contact us via WeChat/WhatsApp: +8619914754015

Submit your inquiry, and we will provide you with a professional solution.

{{ variable.name }}

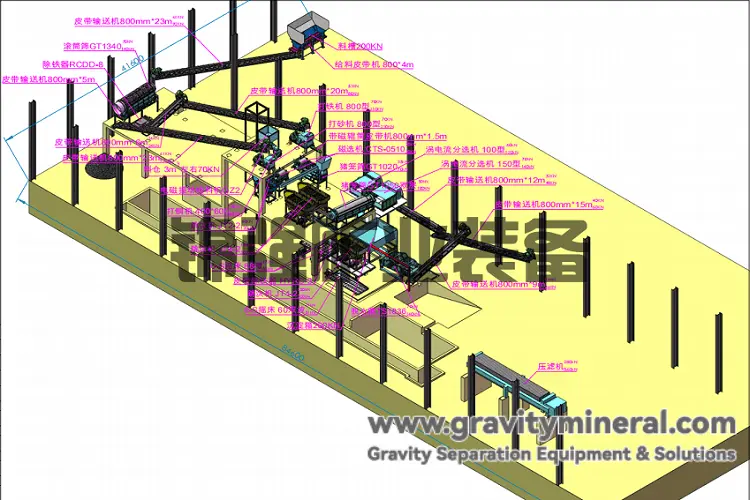

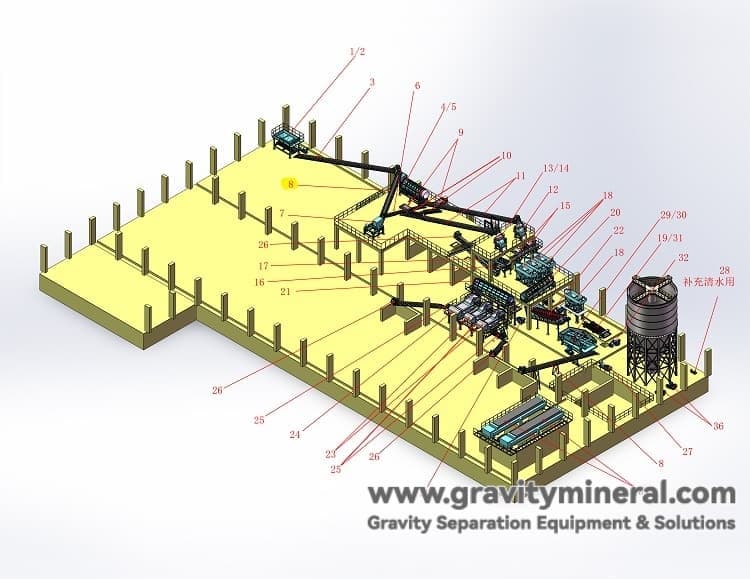

With the acceleration of urbanization, the incineration of domestic waste for power generation has become the mainstream treatment method, but the bottom ash residue generated after incineration still contains a large amount of recyclable metal resources.GravityMineral, with its profound technical accumulation in the field of metal mineral sorting, has innovatively developed a total solution of "multi-stage crushing-intelligent sorting-resourceful utilization" for the characteristics of bottom ash residue from waste incineration. The waste incineration bottom ash sorting solution through crushing, screening, magnetic separation, eddy current sorting and gravity sorting and other physical methods, efficient recovery of iron, copper, aluminum, stainless steel and precious metals and other valuable resources, incineration bottom ash resource utilization rate of 100%, zero landfill of solid wastes, both significant economic and environmental benefits.

Uniform feeding:

Plate feeder evenly conveying to ensure stable operation of subsequent processes

Grizzly screen removes large debris and protects subsequent equipment.

Crushing and shaping:

Specialized incineration bottom ash crusher for coarse crushing + fine crushing and shaping

Iron machine, copper machine to separate the adhering metal

Screening and grading:

Tumbler screen for multi-stage grading, improve the efficiency of sorting

Vibrating screen accurately classifies and creates conditions for sorting.

Magnetic separation recovery:

Multi-stage permanent magnetic separator for efficient recovery of ferrous metal

Strong magnetic separator ensures that the recovery rate of ferrous metal is ≥95%.

Eddy current sorting:

Eddy current sorting machine extracts copper, aluminum and other non-ferrous metals

High sorting efficiency, recovery rate ≥ 90

Gravity sorting:

Jigger + shaker for fine separation of precious metals and heavy minerals

High-grade copper, stainless steel and trace precious metals can be obtained.

Fine screening:

High frequency vibrating screen for fine classification

Ensure the purity of metal products

Dewatering:

Screw sand washer for cleaning and dewatering

Filter press to realize the separation of slag and water

Resource utilization:

Tailings meet the standard of building materials and can be used for making bricks, road base materials, etc.

Metal products are categorized and packaged for direct sale

| System Category | Core Equipment | Technical Characteristics | Processing capacity |

|---|---|---|---|

| Feeding System | Plate feeder | Wear-resistant, uniform feeding | 200-2000t/d |

| Crushing System | Special crusher for incineration bottom ash | Anti-tangling, strong processing capacity | 200-2000t/d |

| Screening system | Tumbler screen | Wear-resistant screen, accurate classification | 200-2000t/d |

| Magnetic separation system | Permanent magnetic separator | Multi-stage magnetic system, high recovery rate | 200-2000t/d |

| Eddy current sorting | Eddy current sorting machine | High sorting efficiency, strong adaptability | 200-2000t/d |

| Gravity separation | Jigger+Shaker | Fine sorting, recovery of precious metals | 200-2000t/d |

| Dewatering system | Filter press | Good dewatering effect, high degree of automation | 200-2000t/d |

| Control system | PLC control system | Automatic operation, easy to operate | Full system control |

Iron metal

Copper metal

Aluminum

Stainless steel

Precious metals: Effective recovery of gold, silver and other trace precious metals.

Tailings products: in line with GB/T25032-2010 building materials standards

Multi-stage sorting process: magnetic separation + eddy current + gravity joint process to ensure efficient recovery of various metals.

High-efficiency sorting equipment: special equipment optimized for the characteristics of incineration bottom ash slag design

Resource utilization: realize metal recovery and comprehensive utilization of tailing slag

Fast return on investment: 10-18 months to recover investment costs

Low operating costs: high degree of automation, low labor costs

Continuous and stable income: stable and considerable income from metal sales

Low maintenance cost: high reliability of equipment, easy maintenance

Green production: the whole process of physical sorting, no chemical additives

Recycling: water recycling, zero wastewater discharge.

Zero solid waste to landfill: 100% resource utilization rate, environmentally friendly.

Energy saving and consumption reduction: energy-saving design of the equipment reduces energy consumption.

We provide all kinds of customers with a full range of solutions for domestic waste power plant incineration bottom ash sorting, services covering project design, equipment installation and system commissioning of the whole process. The following are some typical project cases:

A state-owned enterprise in Jiangsu, China: 1000 tons / day incineration bottom ash treatment project

A listed company in China: 1200 tons / day incineration bottom ash treatment project

A professional incineration bottom ash operation enterprise: 500 tons / day incineration bottom ash treatment project

A private enterprise in China: 600 tons / day incineration bottom ash treatment project

A large-scale enterprise in Vietnam: 1000 tons/day incineration bottom ash treatment project

With mature technology and rich project experience, we provide customers with stable and reliable overall waste incineration bottom ash sorting solutions, and help all kinds of incineration bottom ash resource utilization projects to operate efficiently.

Focus: Maximize metal recycling

Investment characteristics: relatively concentrated, fast return

Applicable objects: existing mainstream demand

Extended functions: metal recycling + deep processing of tailings

Output products: metal + building materials

Comprehensive benefits: realize the full quantitative utilization of solid waste

Pre-consultation: site planning, process design, drawing issuance, equipment selection

Mid-term implementation: equipment manufacturing, installation guidance, commissioning optimization

Post-implementation support: personnel training, operation and maintenance, technology upgrade

Personalized design: according to the treatment capacity, site, budget customized program

Modular configuration: flexible combination of equipment to adapt to different needs

Technical support: 24-hour response, remote diagnosis + on-site service.

We have rich experience in waste incineration bottom ash treatment projects, can provide customers with the most cost-effective solutions.

Contact us for professional technical advice and customized waste incineration bottom ash sorting solution quotes!

GravityMineral - turning waste incineration bottom ash into treasure and creating new value for resource recycling!

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.